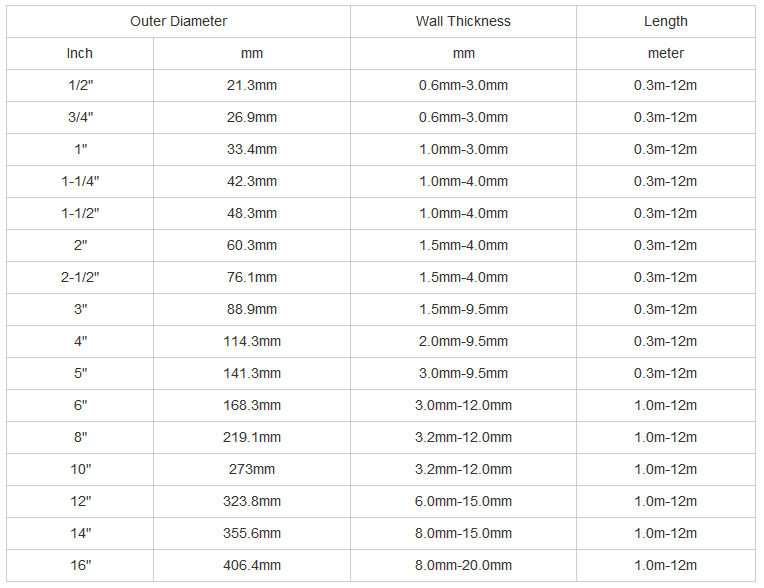

Hot dipped galvanized round pipe/square pipe/rectangular pipe

Short Description:

Hot dipped galvanized round pipe

The raw material is a bundle of steel stripe, which are welded and processed to become the circular pipe model we see. Then, polishing, welding, cutting, and treating the burrs at the interface turn into black different length welded pipe.

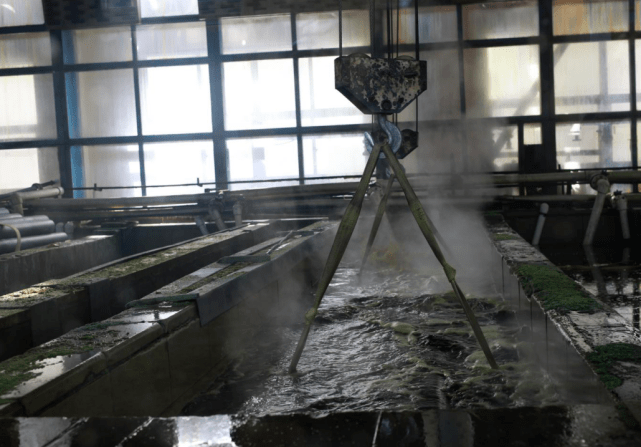

Three acid pickling tests are required before galvanizing ,the purpose of pickling is to remove iron oxide from the surface of steel pipes. After pickling, cleaning is carried out in a tank with ammonium chloride or zinc chloride aqueous solution or a mixture of ammonium chloride and zinc chloride aqueous solution

After being baked, the steel pipe is sent to the zinc pot by the galvanizing machine for galvanizing, and then removed from the zinc pot. The surface of the steel pipe is immersed in a liquid zinc layer. Immediately after galvanizing, the steel pipe is sprayed with steam and compressed air to remove excess zinc from the surface and ensure a uniform and smooth coating surface. The galvanized steel pipe can be passivated as needed

Round steel pipe

Rectangular steel pipe

Square steel pipe

Product packaging

2. above OD 219mm in bulk or according to custom opinion

20GP: can load 25 tons max, steel pipe length should be 5800mm max.

40GP: can load 25 tonx max, steel pipe length should be 11800mm max.

Quality inspection

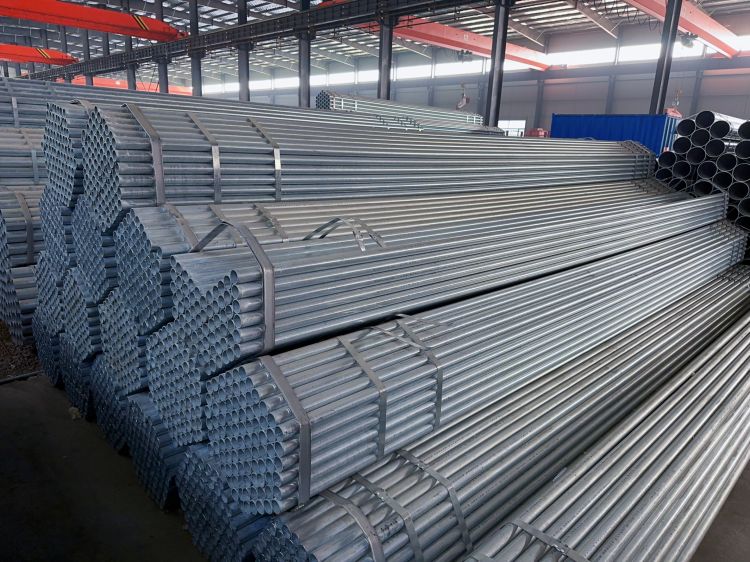

Application of galvanized steel pipe

Hot dipped galvanized steel round pipe(HDG),is widely used in kinds of industry and building areas all over the world

It can be used in construction,machinery, coal mine, chemical industry, electric power, railway vehicles, automobile industry, highway, bridge, container, sports facilities, agricultural machinery, petroleum machinery,prospecting machinery and other manufacturing industries.