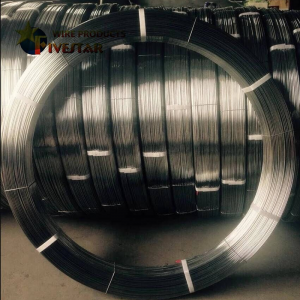

Hot dipped galvanized common nails

Short Description:

Hot dipped galvanized nails (HDG NAILS)

There are three types of galvanization – electro-galvanization, mechanical galvanization, and hot-dip galvanization. Nowadays, hot-dip galvanization is mostly used, so as to ensure protection to iron and steel surfaces from corrosion. In short, galvanized nails are nothing other than those steel or iron nails, that are coated with zinc, so as to prevent corrosion. In hot-dip galvanization, the steel is passed through molten zinc, with a temperature of 860°F. This coating, when exposed, forms a layer of zinc oxide and zinc carbonate. This prevents the inner steel or iron from getting exposed to atmospheric elements that cause corrosion. So, galvanized nails are more durable than regular nails.

HDG COMMON NAILS

Nails size Nails Diameter Nails length

3d g14-1/2 1.25"

4d g14 1.5"

5d g14 1.75"

6d g12-1/2 2"

7d g12-1/2 2.25"

8d g11-1/2 2.5"

10d g10-1/2 3"

16d g10 3.5"

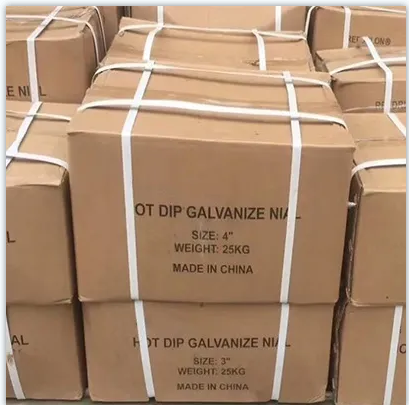

20d g9 4"

HDG RING NAILS

Mateiral: Carton steel /Stainless steel

Shank: Ring

Surface: Zinc coated/Black

Length: 1-1/4" to 6"

Head: Flat head

Diameter:2.0mm to 5.16mm

Packing: 1lbs 2lbs 55lbs per box

HDG SPIRAL NAILS

Spiral shank nails offer good holding power and are specifically designed for use with hardwoods and dense materials. Flooring, siding, decking, pallets and truss rafters are typical applications for spiral shank nails.

Specification:

- Spiral Shank

- Hot Dipped Galvanized

- 8d 2-1/2" (6.35cm)

- 1 Box - 0.88lb (0.4kg)

Feature

- Ideal for general construction, carpentry and framing

- Spiral shank for greater holding power, flat head, diamond point

- For use on exterior applications and with all treated lumber

- Galvanized to meet or exceed ASTM A 153 Class D

Comparison between hot-dip galvanizing and mechanical galvanizing

The comparative advantage of hot-dip galvanizing compared to hot-dip galvanizing is that the galvanized layer of the hot-dip galvanizing process is used for the basic long-term outdoor anti-corrosion coating process of steel. This process is used for large-scale steel parts (transmission towers, engineering steel structures, etc.) for galvanizing and anti-corrosion, and cannot be questioned. However, on the hot-dip galvanizing of fastening parts used outdoors, the domestic process implementation is mainly manual operation, coupled with the characteristics of the hot-dip galvanizing process, Compared with the characteristics of mechanical galvanizing process, there are advantages and disadvantages in the application of the process. For example, when hot-dip galvanizing is used for gaskets and small parts, the parts are prone to adhesion, and when plating threaded parts, the molten zinc coating will block the threads, and the nuts must be plated and re buckled; Smoke, dust, and metal hot vapor pollution are severe, and mechanical galvanizing process does not have such shortcomings. In addition, the surface of mechanical galvanizing coating is smoother and brighter than that of hot-dip galvanizing; For environmental protection, it is a comparable cleaning process.

Functionally, the hot dip galvanizing process of high-temperature melting can cause annealing and softening of the surface of quenched high-strength fastening parts, such as 8.8 grade high-strength steel highway guardrail fasteners. When using hot dip galvanizing, tensile tests conducted according to technical standards reflect unqualified or unstable product quality. Mechanical galvanizing does not cause annealing effects on the surface of quenched steel parts under room temperature conditions.

The mechanical galvanized coating also has the function of resisting atmospheric acid rain. Through experimental comparison, its antibacterial acid rain ability is three times that of the hot-dip galvanized coating. For example, mechanical galvanized parts with the same coating thickness and hot-dip galvanized parts soaked in 10% to 15% dilute sulfuric acid solution will have an acid corrosion exposure time, and the mechanical galvanized coating will be delayed by three times compared to the hot-dip zinc coating. This acid rain resistant function will be particularly important for outdoor power tower fastening parts with severe acid rain in the atmosphere.

No matter what kind of hot-dip nails you need, we can provide them!