China EU STANDARD AISI SS304 30L BEER BARREL/KEG supplier

Short Description:

Professional supplier steel products since 1998! Stainless steel container manufacturing field expert,The industry has advanced beer barrel testing laboratory,The company’s products are exported to more than 40 countries and regions on five continents.

Euro 30L AISI 304 Stainless beer barrel

Euro beer barrel /Keg are a standard size of keg commonly used in Europe and many other countries. They are typically made of stainless steel and have a cylindrical shape with a single opening at the top and a valve at the bottom. The opening at the top is sealed with a removable cap, and the valve at the bottom is used to dispense the beer.

30 L

S type spear

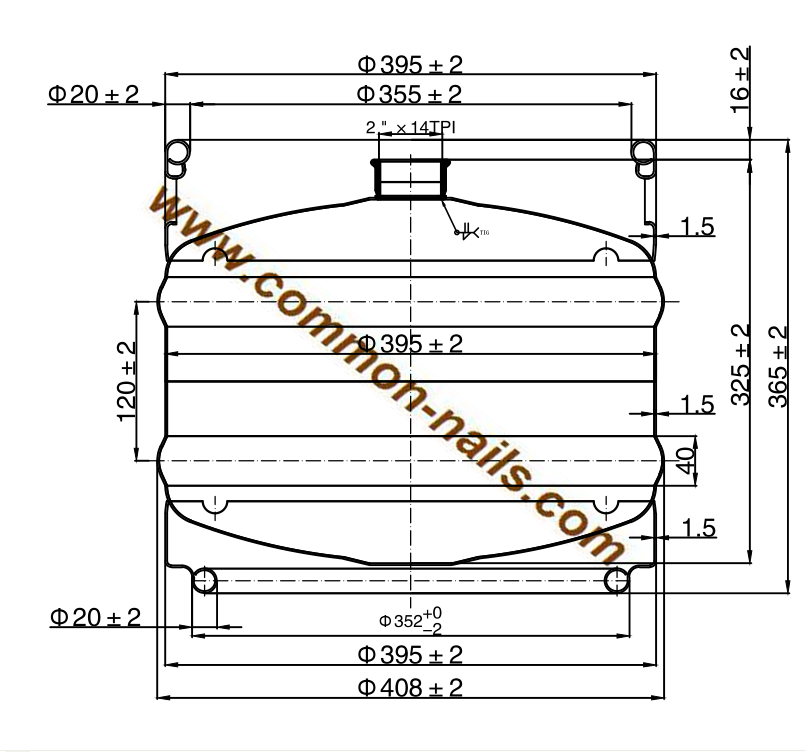

| Technical Data | ||||||||

| Standard

Euro/L |

Material | Capacity

L |

Out diam

mm |

High

mm |

Thickness

mm |

Weight

kg |

Neck | S type spear

mm |

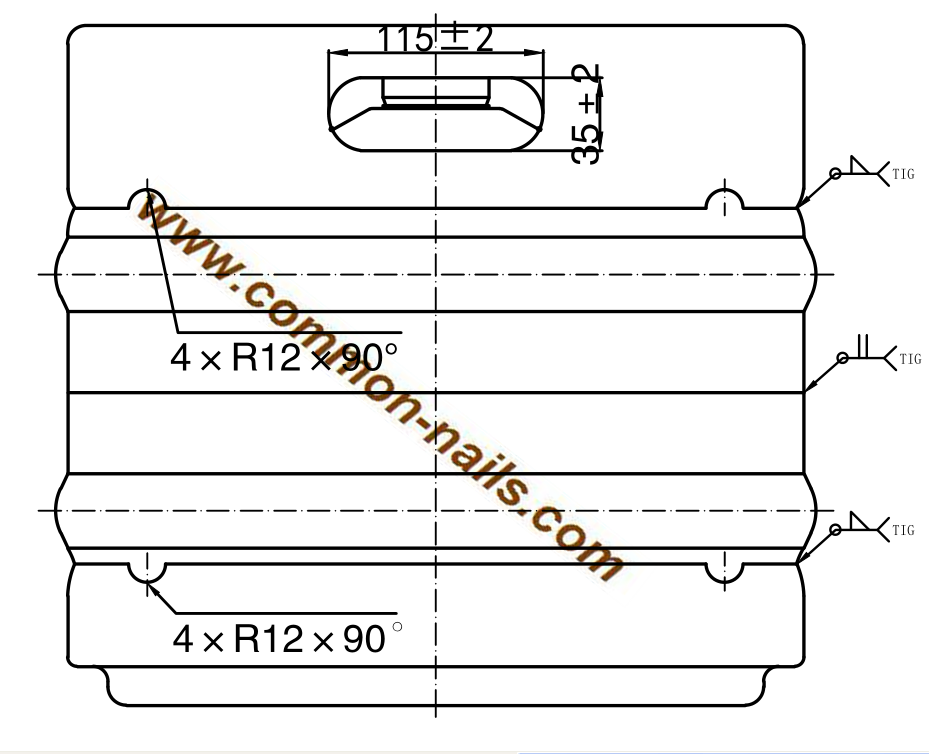

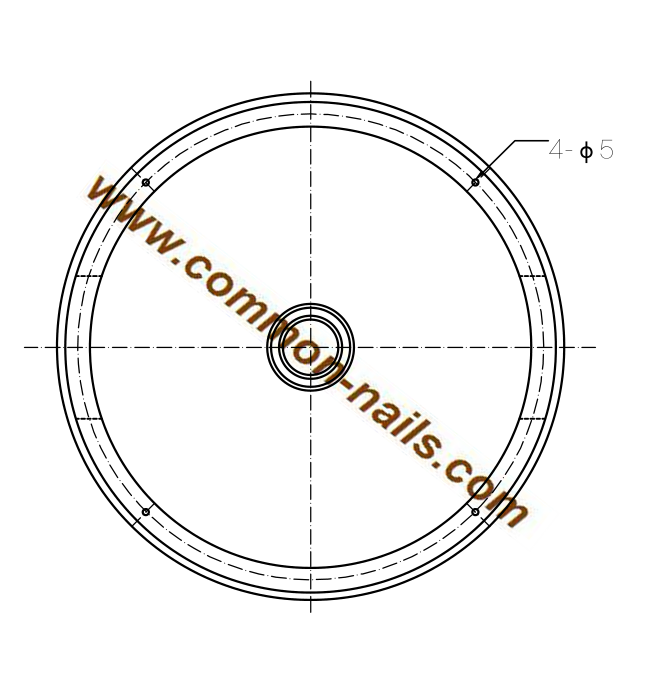

| Euro 30L | Aisi 304 | 30 | 408±2 | 365±2 | 1.5mm ±0.08 | 9kg ± 5% | 2” x 14TPI | 311±1mm |

Basic knowledge of stainless steel in stainless steel beer barrels

All metals react with oxygen in the atmosphere to form oxide films on their surfaces. Unfortunately, the iron oxide formed on ordinary carbon steel continues to oxidize, causing corrosion to expand and eventually forming pores. Coatings or oxidation resistant metals such as zinc, nickel, and chromium can be used for electroplating to ensure the surface of carbon steel, but as is well known, this protection is only a thin film. If the protective layer is damaged, the steel underneath begins to rust

Steel that is resistant to weak corrosive media such as air, steam, water, and chemical corrosive media such as acid, alkali, and salt. Also known as stainless acid resistant steel. In practical applications, steel that is resistant to weak corrosive media is often referred to as stainless steel, while steel that is resistant to chemical media is referred to as acid resistant steel. Due to the difference in chemical composition between the two, the former may not be resistant to chemical corrosion, while the latter generally has non rusting properties. The corrosion resistance of stainless steel 2 depends on the alloy elements contained in the steel. Chromium is the basic element that gives stainless steel corrosion resistance. When the chromium content in steel reaches about 12%, chromium reacts with oxygen in the corrosive medium to form a thin oxide film (self passivation film) on the surface of the steel, which can prevent further corrosion of the steel substrate. In addition to chromium, commonly used alloying elements include nickel, molybdenum, titanium, niobium, copper, nitrogen, etc., to meet the requirements of various applications for the microstructure and properties of stainless steel.

Packing & Shipping

| Loading quantity | |||

| Model | 20GP | 40GP | 40HQ |

| EURO 30L | 510PCS | 1020PCS | 1190PCS |