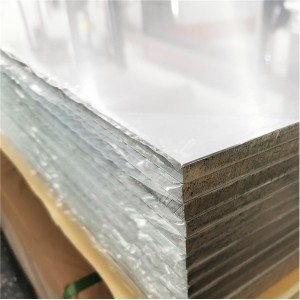

1050 H24 Aluminum coil supplier

Short Description:

1050 aluminum coil belongs to the pure aluminum coil series and also belongs to the 1 series products. The aluminum content of 1050 aluminum coil is 99.50%. Therefore, there is also the name pure aluminum coil mentioned earlier. Friends who are familiar with 1050 aluminum coils should be well aware that 1050 aluminum coils are similar to 1060 aluminum coils in terms of chemical composition and mechanical properties

MOQ:5TONS

1050 Aluminum coil

1050 aluminum coil contains over 99.5% aluminum and is a type of industrial pure aluminum. 1050 aluminum coil has the characteristics of high plasticity, corrosion resistance, good conductivity and thermal conductivity, but its strength is relatively low., 1050 aluminum strip is a product in the pure aluminum plate series, and its chemical composition and mechanical properties are similar to those of 1060 series products. It is basically replaced by 1060 aluminum strip in applications. The last two Arabic numerals of the 1050 series ※ are 50. According to international brand naming principles, products with an aluminum content of 99.5% or higher are considered qualified. The technical standard for aluminum alloys in China (GB/T3880-2006) also specifies that the aluminum content of 1050 should reach 99.5%. Due to the absence of other technical elements, the production process is relatively simple and the price is relatively cheap, making it a commonly used series in conventional industry. Industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, good conductivity and thermal conductivity, but its strength is low, it is not strengthened through heat treatment, and its cutting performance is poor. It can accept contact welding and gas welding.

|

Alloy |

1050 |

|

Temper |

O,H12,H14,H16H18,H19,H22,H24,H26,H28,H32,H34,H36,H38 |

|

Thickness (mm) |

0.3-8.0 |

|

Width (mm) |

100-2650 |

|

Length (mm) |

customized |

1050 aluminum coil chemical composition table

| 铝 Al(%) | 硅 Si (%) | 铜 Cu (%) | 镁 Mg(%) | 锌 Zn (%) | 锰 Mn(%) | 钛 Ti(%) | 钒 V (%) | 铁 Fe(%) |

| 99.50% | 0.30 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 0.05 | 0.40 |

1050 aluminum coil characteristics

Industrial pure aluminum has the general characteristics of aluminum, with low density, good conductivity and thermal conductivity, corrosion resistance, and good plastic processing performance. It can be processed into plates, strips, foils, and extruded products, and can be used for gas welding, argon arc welding, and spot welding.

Industrial pure aluminum cannot be strengthened through heat treatment, but its strength can be improved through cold deformation. The only form of heat treatment is annealing, and the starting temperature of recrystallization is related to impurity content and deformation degree, generally around 200 ℃. The σ b of the annealed sheet is 80-100MPa, σ0.2=30~50MPa,ζ=35%~40%,HB=25~30。 After 60% to 80% cold deformation, although the pressure can be increased to 150-180MPa, the zeta value decreases to 1% to 1.5%. Increasing the content of iron and silicon impurities can improve strength, but reduce plasticity, conductivity, and corrosion resistance. The annealing softening characteristics and cold work hardening characteristics of 1200 (L5) industrial pure aluminum plate are shown in the figure. From the figure, it can be seen that adjusting the annealing temperature after cold deformation or controlling the amount of cold deformation after annealing can achieve mechanical properties in different cold work hardening states. To improve formability, it is better to adopt the first method.

Specification for heat treatment of 1050 aluminum coils

1) Complete annealing: heating at 390-430 ℃; Depending on the effective thickness of the material, the insulation time ranges from 30 to 120 minutes; Cool with the furnace at a speed of 30-50 ℃/h to below 300 ℃, then air cool.

2) Rapid annealing: heating at 350-370 ℃; Depending on the effective thickness of the material, the insulation time ranges from 30 to 120 minutes; Air or water cooling.

3) Quenching and aging: Quenching at 500-510 ℃, air-cooled; Artificial aging at 95-105 ℃ for 3 hours, air-cooled; Natural aging at room temperature for 120 hours.

Mechanical properties of 1050 aluminum coil

Tensile strength σ b (MPa): 60-100

Elongation rate δ/(%): ≥ 23

Elongation rate 50mm/(%): ≥ 25

Note: Longitudinal mechanical properties of pipes at room temperature

Sample size: All wall thicknesses

1050 aluminum coil density: 2.71

1050 aluminum coil standard

Aluminum plate and strip gj standard (GB/T 3880-2006), a unified standard applicable to aluminum alloy plate and strip materials